| Availability: | |

|---|---|

| Quantity: | |

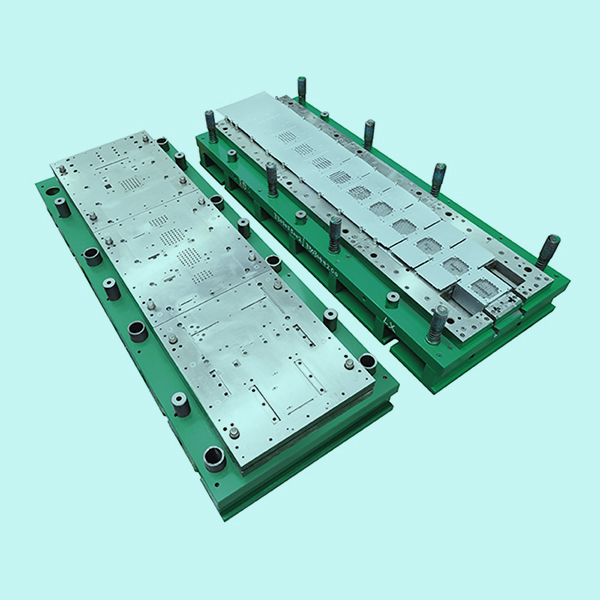

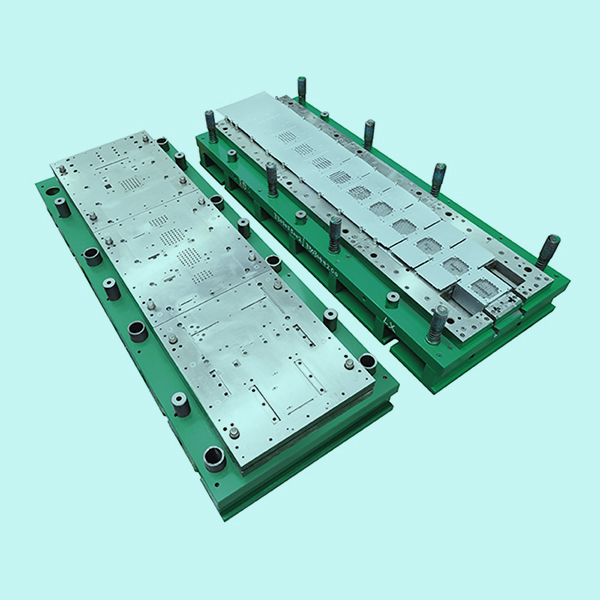

Auto Parts

Machine manufacturer

Mould

| Cooltant system | working light | leveling wedges | foundation screw | wheel flange |

| wheel balance arbor | magnetic chuck | standard wheel | operation manual | wheel dressing base |

| PLC controller | touched screen |

diamond pen | magnetic separator | wheel balance stand | DRO | dust collection |

Description | Unit | SG50100PC2 | SG50120PC2 | ||

Table size(L*W) | mm | 1000*500 | 500*1200 | ||

Max.grinding size of workpiece(L*W) | mm | 1000*500 | 500*1200 | ||

Distance from spindle center to table surface | mm | 820 | 850 | ||

Magnetic chuck size | mm | 500*1000 | 500*1200* | ||

Table longitudinal speed | mm | 5-25 | |||

Max. loading of table(including magentic chuck) | kg | 800 | 1200 | ||

Wheelhead Transverse moving | Auto intermittent feed rate | m/t | 1-20 | ||

Rapid speed feed | m/min | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.005 | |||

Wheel vertical moving | Auto intermittent speed | mm/t | 0.005-0.045 | ||

Rapid speed feed | m/min. | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.005 | |||

Wheel size(OD*Width*ID) | mm | 355*50*127 | |||

Surface roughness | μm | Ra0.63 | |||

Gross weight | kg | 6000 | 6500 | ||

Package dimension(L*W*H) | cm | 400*220*172 260*227*255 | 480*220*172 260*227*255 | ||

Description | Unit | SG60120PC2 | SG60160PC2 | SG60220PC2 | |

Table size(L*W) | mm | 1250*610 | 1600*610 | 2200*610 | |

Max.grinding size of workpiece(L*W) | mm | 1250*610 | 1600*610 | 2200*610 | |

Distance from spindle center to table surface | mm | 600/900 | 600/900 | 600/900 | |

Magnetic chuck size | mm | 600*1200*1 | 600*800*2 | 600*1000*2 | |

Table longitudinal speed | mm | 5-25 | |||

Max. loading of table(including magentic chuck) | kg | 1230 | 1690 | 6000 | |

Wheelhead Transverse moving | Auto intermittent feed rate | m/t | 1-20 | ||

Rapid speed feed | m/min | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.05 | |||

Wheel vertical moving | Auto intermittent speed | mm/t | 0.005-0.05 | ||

Rapid speed feed | m/min. | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.005 | |||

Wheel size(OD*Width*ID) | mm | 355*50*127 | |||

Total rated power | KW | 7.5 | |||

Roughness | μm | Ra0.63 | |||

worktable Max. loading weight | kg | 970 | 1230 | 1690 | |

Gross weight | kg | 7000 | 8000 | 9000 | |

Package dimension(L*W*H) | cm | 450*220*172 260*227*255 | 480*220*172 260*227*255 | 600*220*172 260*227*255 | |

Special grinding head spindle with precision rolling bearings, fully sealed lubrication, long life and high precision.

The three axes guide rails are plasticized, with independent automatic lubrication device, smooth and smooth movement, small wear and stable precision.

Program-controlled series: YZ axis adopts AC servo motor and PLC system control, which can realize automatic grinding of flat or forming surface.

CNC series: YZ axis feed adopts precision ball screw, controlled by AC servo motor and CNC system, with high sensitivity of tool feeding, which can realize plane and forming surface (YZ axis linkage can realize shaped grinding wheel dressing, thus realizing forming surface grinding), unequal distance and unequal depth and unequal width groove or step automatic grinding, with convenient operation and high efficiency.

The X-axis (left and right) is driven by hydraulic pressure, with photoelectric switch signaling, electro-hydraulic valve reversing, and independent hydraulic station, with smooth operation and low noise.

Auto Parts

Machine manufacturer

Mould

| Cooltant system | working light | leveling wedges | foundation screw | wheel flange |

| wheel balance arbor | magnetic chuck | standard wheel | operation manual | wheel dressing base |

| PLC controller | touched screen |

diamond pen | magnetic separator | wheel balance stand | DRO | dust collection |

Description | Unit | SG50100PC2 | SG50120PC2 | ||

Table size(L*W) | mm | 1000*500 | 500*1200 | ||

Max.grinding size of workpiece(L*W) | mm | 1000*500 | 500*1200 | ||

Distance from spindle center to table surface | mm | 820 | 850 | ||

Magnetic chuck size | mm | 500*1000 | 500*1200* | ||

Table longitudinal speed | mm | 5-25 | |||

Max. loading of table(including magentic chuck) | kg | 800 | 1200 | ||

Wheelhead Transverse moving | Auto intermittent feed rate | m/t | 1-20 | ||

Rapid speed feed | m/min | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.005 | |||

Wheel vertical moving | Auto intermittent speed | mm/t | 0.005-0.045 | ||

Rapid speed feed | m/min. | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.005 | |||

Wheel size(OD*Width*ID) | mm | 355*50*127 | |||

Surface roughness | μm | Ra0.63 | |||

Gross weight | kg | 6000 | 6500 | ||

Package dimension(L*W*H) | cm | 400*220*172 260*227*255 | 480*220*172 260*227*255 | ||

Description | Unit | SG60120PC2 | SG60160PC2 | SG60220PC2 | |

Table size(L*W) | mm | 1250*610 | 1600*610 | 2200*610 | |

Max.grinding size of workpiece(L*W) | mm | 1250*610 | 1600*610 | 2200*610 | |

Distance from spindle center to table surface | mm | 600/900 | 600/900 | 600/900 | |

Magnetic chuck size | mm | 600*1200*1 | 600*800*2 | 600*1000*2 | |

Table longitudinal speed | mm | 5-25 | |||

Max. loading of table(including magentic chuck) | kg | 1230 | 1690 | 6000 | |

Wheelhead Transverse moving | Auto intermittent feed rate | m/t | 1-20 | ||

Rapid speed feed | m/min | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.05 | |||

Wheel vertical moving | Auto intermittent speed | mm/t | 0.005-0.05 | ||

Rapid speed feed | m/min. | 0.05-2 | |||

Handwheel feed per gra. | mm/gra. | 0.005 | |||

Wheel size(OD*Width*ID) | mm | 355*50*127 | |||

Total rated power | KW | 7.5 | |||

Roughness | μm | Ra0.63 | |||

worktable Max. loading weight | kg | 970 | 1230 | 1690 | |

Gross weight | kg | 7000 | 8000 | 9000 | |

Package dimension(L*W*H) | cm | 450*220*172 260*227*255 | 480*220*172 260*227*255 | 600*220*172 260*227*255 | |

Special grinding head spindle with precision rolling bearings, fully sealed lubrication, long life and high precision.

The three axes guide rails are plasticized, with independent automatic lubrication device, smooth and smooth movement, small wear and stable precision.

Program-controlled series: YZ axis adopts AC servo motor and PLC system control, which can realize automatic grinding of flat or forming surface.

CNC series: YZ axis feed adopts precision ball screw, controlled by AC servo motor and CNC system, with high sensitivity of tool feeding, which can realize plane and forming surface (YZ axis linkage can realize shaped grinding wheel dressing, thus realizing forming surface grinding), unequal distance and unequal depth and unequal width groove or step automatic grinding, with convenient operation and high efficiency.

The X-axis (left and right) is driven by hydraulic pressure, with photoelectric switch signaling, electro-hydraulic valve reversing, and independent hydraulic station, with smooth operation and low noise.