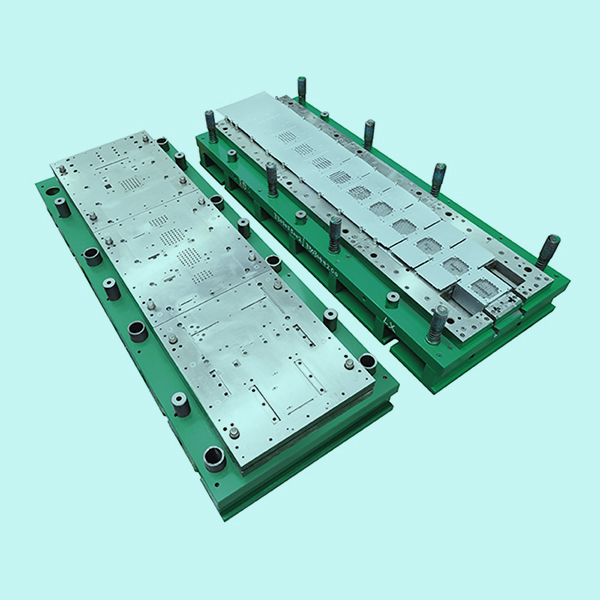

Auto Parts

Machine Manufacturer

Mould

Standard accessories

| Cooltant system | lubrication system | working light | leveling wedges | foundation screw |

| wheel flange | wheel balance arbor | tool and tool box, | Permanent- chuck | standard wheel |

dust collection device | paper filter | magetic separator | wheel balance stand | Y Z axis DRO |

Description | Unit | 618A | MG618A | 818A |

| Table size(L*W) | mm | 460*180 | 460*180 | 480*200 |

Max.travel of table(L*W) | mm | 500*190 | 500*190 | 530*220 |

T-slot of table(No.*width) | mm | 1*14 | ||

Distance from spindle center to worktable | mm | 335 | 440 | 440 |

Wheel size(OD*Width*ID) | mm | 200*13*31.75 | 200*13*31.75 | |

Spindle speed(stepless) | r/min | 2850 | ||

Vertical feed handwheel per revolution | mm | 1.25 | ||

Vertical feed handwheel per division | mm | 0.005 | ||

Transverse feed handwheel per revolution | mm | 5 | ||

Transverse feed handwheel per division | mm | 0.02 | ||

Spindle motor | KW | 1.1 | ||

Cooltant motor | KW | 0.04 | ||

Parallelism of machined surface to base surface | mm | 300:0.004 | 300:0.002 | 300:0.004 |

Surface roughness | μm | Ra0.32 | Ra0.16 | Ra0.32 |

Machine | ||||

Net/Gross weight | kg | 650/750 | 650/750 | 750/850 |

Permanent-magnetic chuck | mm | 400*150 | 400*200 | |

Package dimension(L*W*H) | mm | 1000*1150*1760 | 1140*1250*1940 | |

High strength cast iron foundation

Machine transverse movement adotps saddle moving double V guide rail structure with TEflon soft belt to improve guide positioning accuracy and reduce friction

Column adopts double wall structure to improve rigidity

Grinding head adopts high precision rolling bearing spindle set, sleeve mounted, can achieve high precision and high finish grinding

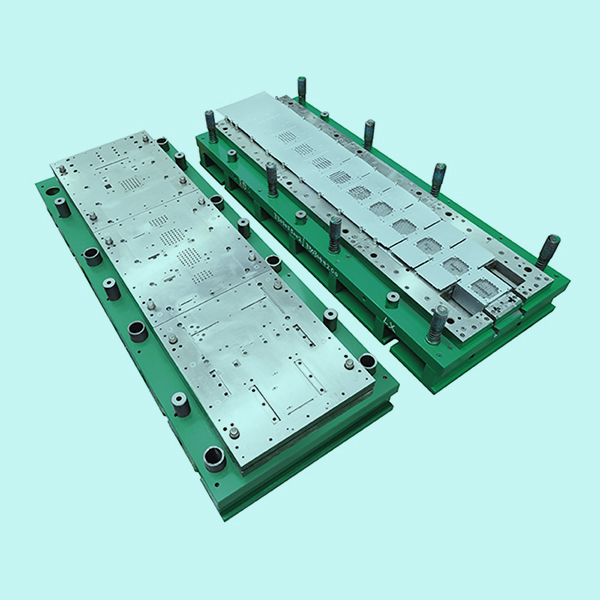

Auto Parts

Machine Manufacturer

Mould

Standard accessories

| Cooltant system | lubrication system | working light | leveling wedges | foundation screw |

| wheel flange | wheel balance arbor | tool and tool box, | Permanent- chuck | standard wheel |

dust collection device | paper filter | magetic separator | wheel balance stand | Y Z axis DRO |

Description | Unit | 618A | MG618A | 818A |

| Table size(L*W) | mm | 460*180 | 460*180 | 480*200 |

Max.travel of table(L*W) | mm | 500*190 | 500*190 | 530*220 |

T-slot of table(No.*width) | mm | 1*14 | ||

Distance from spindle center to worktable | mm | 335 | 440 | 440 |

Wheel size(OD*Width*ID) | mm | 200*13*31.75 | 200*13*31.75 | |

Spindle speed(stepless) | r/min | 2850 | ||

Vertical feed handwheel per revolution | mm | 1.25 | ||

Vertical feed handwheel per division | mm | 0.005 | ||

Transverse feed handwheel per revolution | mm | 5 | ||

Transverse feed handwheel per division | mm | 0.02 | ||

Spindle motor | KW | 1.1 | ||

Cooltant motor | KW | 0.04 | ||

Parallelism of machined surface to base surface | mm | 300:0.004 | 300:0.002 | 300:0.004 |

Surface roughness | μm | Ra0.32 | Ra0.16 | Ra0.32 |

Machine | ||||

Net/Gross weight | kg | 650/750 | 650/750 | 750/850 |

Permanent-magnetic chuck | mm | 400*150 | 400*200 | |

Package dimension(L*W*H) | mm | 1000*1150*1760 | 1140*1250*1940 | |

High strength cast iron foundation

Machine transverse movement adotps saddle moving double V guide rail structure with TEflon soft belt to improve guide positioning accuracy and reduce friction

Column adopts double wall structure to improve rigidity

Grinding head adopts high precision rolling bearing spindle set, sleeve mounted, can achieve high precision and high finish grinding